CONTROL SYSTEM

Features

The control system introduces an industrial grade computer that all casting parameters can be set on it. It is a close loop and auto feed back system with self-diagnosis, self-correction and self monitoring. Each function is described as below:

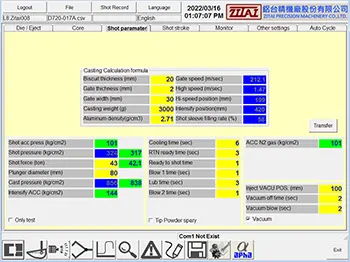

SHOT PARAMETER SETTING

The close loop system stands for self-data feedback, self-diagnostic and self correction all at once which becomes easier and more accurate.

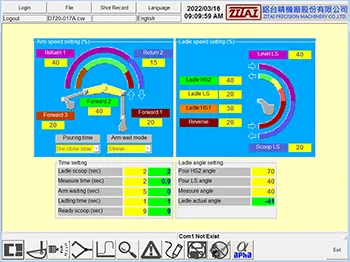

AUTO LADLE PARAMETER SETTING

Molten aluminum feeding speed and volume is controlled by potentiometer sensor. Biscuit thickness is assured by preset value.

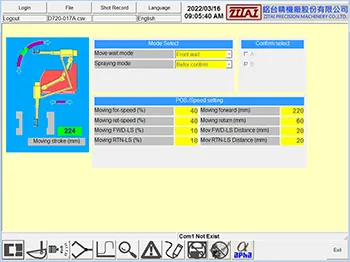

AUTO EXTRACTOR PARAMETER SETTING

Movement of extractor is also controlled by potentiometer and this makes user-friendly parameter setting possible such as speed, distance and even easier for data management.

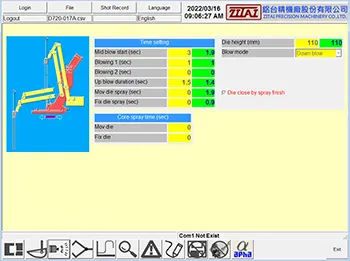

AUTO SPRAYER PARAMETER SETTING

Spraying time of chemical agent is to be sent from the control panel, even Auto sprayer’s position is adjustable by the same method according to various die height.

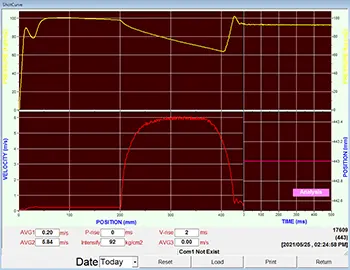

SHOT GRAPHIC DISPLAY

This graphic display of velocity and pressure for each shot ensures the casting quality which is guaranteed.